Thanks to continued improvements in thermal imaging hardware, software and drone technology, it is now possible to improve the efficiency and accuracy of photovoltaic (PV) inspections more than ever. The current practice of manual electric testing is not sustainable at scale and results in slower PV system buildouts, increased inefficiencies in identifying potential equipment and construction problems and delayed repairs to faulty panels and balance of system (BOS) components.

To complement and enhance manual electrical testing, the use of drone thermal imaging for PV inspections, also known as aerial thermography, is increasingly required in contracts for PV system commissioning and maintenance due to the speed and level of detail that the technology package can provide. Whereas the manual inspection of a small PV system may take hours or days, a drone thermal imaging inspection of hundreds of acres, including panel cell-level defect analysis, can be accomplished in a single day.

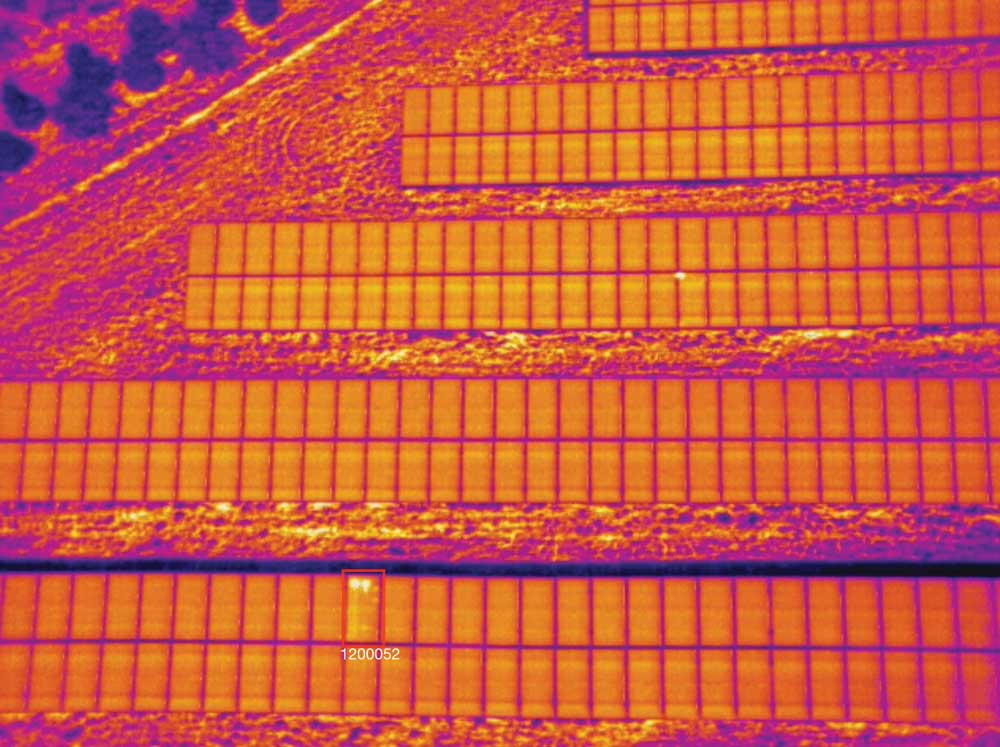

Longwave infrared (LWIR) cameras, also known as thermal cameras, detect the infrared band of the electromagnetic spectrum, which allows them to “see” in total darkness and through obscurants such as fog and smoke, measure temperature and accurately detect anomalies. Aerial thermal imaging cameras make it easy to quickly inspect a large target area and pinpoint solar panel problems. They streamline the completion of a qualitative analysis by allowing the operator to quickly see heat differentials across a solar field and identify possible impairments.

An aerial RGB (red green blue) or visible-light camera helps detect non-electrical issues like soiling, shading, bird excrement and animal nesting. A thermal-only payload could potentially lead to false positives by misidentifying these same issues as electrical anomalies. Pairing thermal cameras with RGB cameras in a drone sensor suite provides both the required visible awareness and context to effectively and accurately spot anomalies in the field.

With the results of a professional drone inspection that combines thermal and RGB imaging data, a PV testing technician can more efficiently execute manual electrical testing on only the impaired PV panels. However, the practice does require as much, if not more, training than what is required for manual IV Curve Tracing. Additionally, to ensure sensor performance and temperature measurement accuracy, aerial thermographers must consider environmental conditions, such as wind, temperature and humidity, as well as hardware factors, such as flight speed, resolution and frame rate, which may affect the success of the drone-based thermal inspection.

In addition to keeping in mind the aforementioned limitations of thermal imaging for PV inspections, it’s also worth mentioning that the return on investment (ROI) is viewed as time saved and efficiency, so it is critical to understand up front how long the process will take. In order to ensure drone PV inspections are successful, drone PV inspection strategies need to account for start time and flight schedule, duration of flight, data processing time, bad weather plans, extra flights and the final report deliverable timeline.

As countries, states and cities begin to increase the production and utilization of solar panels for renewable energy, the need to inspect and maintain these critical assets will become vital to managing costs and efficiency. The rise in drone technology is proving to be a crucial tool for inspecting both small and large solar fields alike. As thermal sensor, software and platform technology continues to evolve, so will the techniques for collecting and processing thermal data, making it easier to ensure compatibility with workflows and company procedures. As thermal drone solar inspections become more mainstream, asset owners and energy companies will need to determine whether outsourcing or developing in-house programs makes the most sense for their long-term goals.

Brett Kanda is UAS business development manager for FLIR Systems Inc.

— Solar Builder magazine

Leave a Reply

You must be logged in to post a comment.