Pictured: Back-of-the-rack grates that protect the backs of modules from overly curious wildlife and reduce the need for fencing.

Within the last year, the Inovateus Solar leadership team determined that they would take the initiative to embrace environmentally friendly solutions across multiple areas of operations. As a renewable energy company, our team felt a responsibility to implement measures that support triple bottom line practices: people, planet and profit. Founded on the mission of “Building a Brilliant Tomorrow,” Inovateus formed an eight-member stewardship team that would generate a new annual report with benchmarks, solutions and goals for more sustainable solar development.

To achieve these goals, Inovateus solar design engineers were tasked with making designs more sustainable by minimizing the use of equipment, reducing potential waste materials and preserving and protecting the land as much as possible. As they began thinking more sustainably, they discovered that sustainable designs could also generate project savings, benefitting customers. With that in mind, here are three tips for designing a more sustainable ground mount solar project.

1. Reduce wiring’s carbon footprint and save on costs

PV wiring can be the source of a large carbon footprint. An excess of wiring increases the use of copper mining, plastic conduit, packaging and the manufacturing and transportation of cables to the job site. Similarly, wiring needs to be recycled or reused at the end of the project’s lifetime. Aside from its carbon footprint, unnecessary wiring also increases project costs.

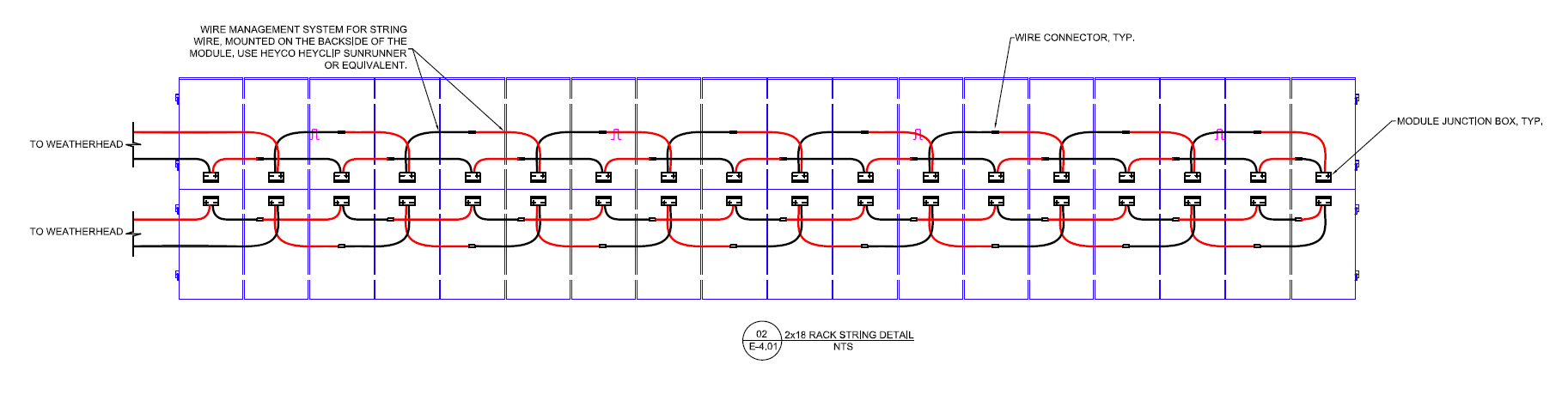

To reduce wiring in ground-mount systems connected in series, Inovateus uses a wire weave technique that strings the negative and positive runs to every other panel. By doing so, the negative and the positive leads finish at the same end of the rack instead of at opposite ends, saving substantial amounts of PV wiring. For example, for a rack with 18 modules, each module is about 3 ft wide. Consequently, this equates to eliminating roughly 54 ft of wire per string. For a PV project with 100 strings, PV designers can save the client 5,400 ft of balance of system (BOS) costs, as well as the wire’s associated carbon footprint.

Designers can further reduce wire footprint and capital costs by using wire branch connectors. Branch connectors allow installers to connect two strings in parallel and use one home run wire to the inverter instead of two. While the wire size (and copper content) will need to be increased to account for the higher amperage, this technique will once again reduce the wiring’s overall carbon footprint — and save nearly 50 percent on wiring costs and its associated labor.

2. Preserve land via higher efficiency solar panels and designs

Solar developers can often be criticized for cutting down trees and “planting” solar panels on land that might otherwise be used for agriculture or recreation. As sustainable solar developers, we want to design projects with the least impact on agricultural land and natural habitats.

One solution for reducing acreage is to utilize high-efficiency solar modules. While high-efficiency panels are more expensive compared with standard ones, this extra cost can be offset by generating more kilowatt-hours (kWh) per square foot and by reducing land leasing or purchasing cost. Furthermore, fewer panels reduces the costs and carbon footprint of racking, wiring and other equipment. More efficient solar modules may include higher wattages, better or higher quality technology or bifacial technology.

Designers can also pack more power per square foot into ground-mount systems by changing the tilt from around 30 degrees to 25 degrees. This design strategy increases the solar panel density, allowing for another row or more to be installed on the same acreage. The increased solar production more than compensates for the efficiency loss. Another option for increasing kWh production is to install solar tracking systems.

3. Plant pollinator grass and reduce fencing

When Inovateus thinks about sustainable solar design, we similarly want to protect and preserve natural habitats. One habitat preservation tactic is to use bee and butterfly pollinator grass mix that provides wild bees, butterflies and insects with a pesticide-free food source. Bee and butterfly pollinator mix can potentially cost more than traditional grass mixes. However, it will reduce operations and maintenance (O&M) costs by decreasing lawn care labor and fertilizer costs, thus creating a net positive savings on O&M.

Another practice to preserve the natural habitat around a solar installation is to minimize fencing. Instead of placing a large perimeter fence around a solar project, Inovateus can install a wire barrier on the back of a fixed tilt racking system. This simple barrier restricts human access to the back of the panels while allowing deer and other wildlife to flow through the project. Another option might be to install fencing with larger gaps (when permitted), allowing various animals to traverse through the fence.

|

“Throw and go” fescue

|

High-Performance & Pollinator-Friendly seed mixes

|

|

| Seed sourcing | Readily available commodity. | Ask your local USDA NRCS office for recommendations. Specialty growers include Ernst Conservation Seeds, Prairie Restorations, Prairie Moon, Roundstone, Pheasants Forever, Bee and Butterfly Habitat Fund, and others. |

| Site prep | Thorough site prep results in more successful establishment. | Thorough site prep results in more successful establishment. |

| Seed availability | Readily available. | Variable year to year. Supplies of specific species can become constrained. |

| Seed weight measure | Pounds per acre (due to relative uniformity of grass seed size). | Seeds per square foot.

When comparing costs to turf, avoid use of pounds per acre measure.

|

| Considerations for meeting Stormwater Pollution Protection Plan (SWPPP) conditions

|

The nickname “throw and go” emerged from these seed mixes being used to fulfill SWPPP conditions. | Best when paired with a fast-establishing cover crop like winter wheat or oats. Cover crop provides short term soil stabilization giving the high-performance seed mixtures time to grow. |

| Equipment used | Broadcast seeder on tractor.

Due to cost of water and other factors, hydroseeding solar arrays is not recommended. |

Tractor to rip and till soil. Broadcast and/or drill seeder on tractor depending on soil, slope and other factors. |

| Skillset of vegetation management staff | Mowing | Integrated Vegetation Management (visual plant identification, then managed through a combination of mowing, spot herbicide)

|

| Cost of individual vegetation management visit | No difference | No difference |

| Frequency of management visits | 3-8x/year for 30 years | 3x/year for first 3 years

1x/year for years 4-30 |

| Frequency of mower/solar collisions | Greater total number of collisions because of more mowings. | |

| Long-term opportunity to sequester soil carbon | Insignificant. Turfgrass roots average 4-6 inch depth. | Significant. The root structures of native forbs and grasses range from 3 to 20 feet. |

| Resilience to extended droughts | Non-resilient. May require watering and/or fertilizer to maintain perennial vegetative cover (a common stormwater control permit condition). | Deep and complex root structures results in soils holding more water, as well as roots being able to access more water. |

| Resilience to intense stormwater events | In 2008, the U.S. Geological Survey completed a five-year storm water study that revealed “striking differences between turf and prairie vegetation.” The study found “prairie vegetation had greater median infiltration rates than those with turf grass.”

|

|

Design is only the first step toward building sustainable solar projects. For other tips on how to build sustainable solar projects, read Inovateus Solar’s first annual sustainability report here.

Jonathan Rienks is project engineer for Inovateus Solar.

— Solar Builder magazine

[source: https://solarbuildermag.com/featured/three-tips-for-sustainable-ground-mount-design/]

Leave a Reply

You must be logged in to post a comment.