SunLink Corp. has launched Precision-Modular RMS, the newest addition to its quality engineered, aluminum Precision RMS solar racking family. In addition to superior layout flexibility, Precision-Modular offers the commercial PV industry more than 30% cost savings over SunLink’s legacy systems — providing unrivaled value without sacrificing the product quality and engineering excellence for which SunLink is well known.

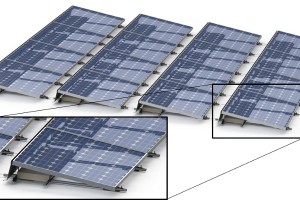

The products that make up the Precision RMS line advance distributed generation by making solar viable for a much larger range of rooftops — even in locations where it wasn’t previously feasible. The inaugural Precision RMS product (released in July 2012) achieved that by making it possible to install solar on roofs with weak decks and in high snow and wind zones. Now, Precision-Modular RMS solves the challenge posed by rooftop obstructions. The system is assembled, laid out and installed module-by-module to maximize layout flexibility and facilitate last minute on-roof changes. The modular approach also significantly shortens design/engineering, shipping and installation timelines.

The products that make up the Precision RMS line advance distributed generation by making solar viable for a much larger range of rooftops — even in locations where it wasn’t previously feasible. The inaugural Precision RMS product (released in July 2012) achieved that by making it possible to install solar on roofs with weak decks and in high snow and wind zones. Now, Precision-Modular RMS solves the challenge posed by rooftop obstructions. The system is assembled, laid out and installed module-by-module to maximize layout flexibility and facilitate last minute on-roof changes. The modular approach also significantly shortens design/engineering, shipping and installation timelines.

“Precision-Modular is the most cost effective roof mount system in our company’s history. We’ve engineered it across the board to ensure a lower total installed cost,” explains SunLink CEO Chris Tilley. “We maintain the system components as part of a standard inventory, which allows us to keep costs down and shorten delivery times. But that’s just the beginning. As with all SunLink roof mount products, the system includes integrated wire management and grounding to make many ancillary electric components unnecessary, and features roof-friendly rubber feet that prevent any metal from touching the roof surface to eliminate the need for slip sheets in most cases.”

Other design features include compact deflectors that enable significantly more project density than other roof mount systems, as well as full connectivity north/south and east/west to better distribute loads, and no reliance on the module frame as a structural element. SunLink also provides customers with a universal jig that auto-aligns and auto-spaces all components to increase installation throughput and improve overall quality. As a bonus, the jig allows module-to-hardware assembly to take place at waist height in a controlled environment.

Precision-Modular is currently available for 60 and 72-cell modules and 10 degree tilt.

— Solar Builder magazine

[source: http://solarbuildermag.com/news/sunlink-introduces-new-solar-rooftop-racking-system/]

Leave a Reply

You must be logged in to post a comment.