One of the most common questions asked by PV Installers, as well as customers, is how to properly size and charge a battery bank in places where ambient temperatures may vary considerably throughout the year.

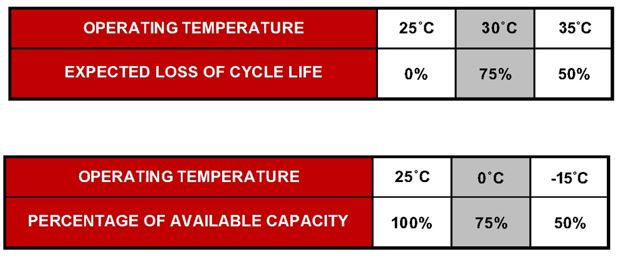

Temperature affects battery performance in two ways. The standard capacity rating of a battery is based on each cell having an electrolyte temperature of 25ºC (77ºF). Temperatures below the nominal 25ºC (77ºF) reduce the battery’s effective capacity and lengthen the time to restore the battery to full charge. Temperatures above 25ºC (77ºF) will slightly increase capacity but also will increase self-discharge and shorten battery life. Although the capacity of a battery will increase as temperatures rise, any cycle life loss due to operating at higher temperatures is not recoverable.

Lower Operating Temperatures: Reduce capacity and maintain longer cycle life.

Higher Operating Temperatures: Maintain capacity, increase the rate of self-discharge and battery wear and shortening battery cycle life.

As ambient temperatures fall below 25ºC (77ºF), the required battery capacity to supply equivalent storage and power will increase. A multiplier is used to calculate the required battery bank capacity in cold temperatures. For example, a battery bank of 1,000 Ah operating at 25ºC (77ºF) would be increased 1,650 Ah to offer the equivalent capacity and performance when the continuous operating temperature lowers to -10˚C (14˚F).

The electrolyte in a fully charged battery has a freezing point of approximately -65ºC (-85ºF). As specific gravity lowers as the battery discharges, a fully discharged battery with low specific gravity has a much higher freezing point just below 0ºC (32ºF). A fully discharged battery is in danger of freezing below 4ºC (40ºF) and should be charged immediately or un-repairable damage will result.

Most chargers use a battery temperature sensor (BTS) mounted to the side of one of the batteries to measure the cell temperatures and regulate the charge voltage accordingly. As cell temperature rises or drops from the 25ºC (77ºF) setpoint, the charger will adjust the charge voltage to compensate accordingly. This ensures the batteries receive the appropriate charge voltage necessary to bring the batteries to full charge without overcharging and/or cell damage.

To operate effectively, the sensor must be properly mounted on the side of the battery case, below the electrolyte level, to provide an accurate reading of cell temperature. Refer to the battery manufacturer for more information and instruction on the effective use of temperature sensors on your particular model.

Jeff Myles is Marketing Manager for Rolls Battery.

— Solar Builder magazine

Leave a Reply

You must be logged in to post a comment.