The following article was sent by the charge controller experts at Morningstar Corp. We are hosting a Morningstar webinar on Nov. 17, covering off-grid innovations. Sign up here to join us live or to watch on-demand.

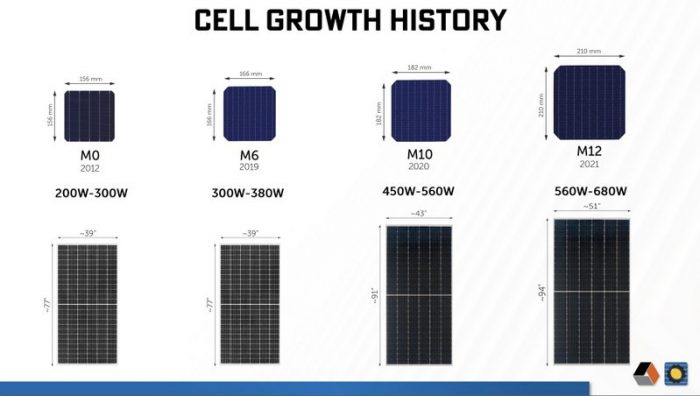

The “large format” 72 cell nominal 24 V solar module has been a staple of industrial and other off-grid solar system design for several decades. Over much of that time, cell and module sizes have been growing. While these increases historically have been linear and incremental, in recent years they’ve been accelerating. A major factor driving this trend is the fact that grid-tied utility-scale residential and commercial solar designers who also deploy 72 cell modules need larger cell sizes to increase the solar module’s total power output.

Because they increase power more cost-effectively, larger cells and modules can accommodate larger loads, and can offer greater solar “autonomy” in regions with more limited sunshine (lower insolation). In addition to upfront cost savings, the extra power from these larger modules can improve battery health at off-grid sites by producing higher average battery state of charge (SOC) when the load the system is running is not increased. Since batteries are often the most expensive component in an off-grid solar system, this greatly improves ROI in terms of battery costs and the time and effort to replace them.

Technology, competition and economies of scale have driven module prices lower over the years, lowering the cost per watt. Module manufactures have also been dialing in the Voc and Isc of these larger modules to help large residential, commercial and utility-scale grid-tied projects benefit from reduced costs associated with combiner boxes, racking, foundation, cabling and installation. These benefits outweigh any negative consequences that large-cell modules might have on large grid-tied system designs.

However, most off-grid systems, typically consisting of just a few modules, are unlikely to see those same cost savings. This means larger modules present the following potential negative consequences for off-grid designers:

Module weight considerations. Heavier modules can increase transportation and installation costs, as well as racking needed. Module weight increases can also affect deployments because OSHA and other regulations (and just practicality) might require two people instead of one to lift larger, heavier modules into position. Although grid-tied projects can also be affected by heavier modules, off-grid projects are more sensitive to them because they oftentimes deploy fewer installers (sometimes just one person), and off-grid systems are more likely to rely on mounts and supports that are not as large and stable as those associated with large utility-scale grid-tied solar systems.

Increased surface area effects. Potential problems here involve areas with higher wind speeds, heavy snowfalls, and more. This is especially a concern with mobile telecom and traffic signaling/warning applications, where systems modified with new modules are moved to new locations that may encounter higher wind velocities.

Other potential downsides

- Newer modules often have different Voc ratings and different Voc temperature coefficients than the older, smaller modules they are replacing. A system designed with components (charge controllers, breakers, fuses and wire sizes) that were initially capable of handling maximum array voltages might not meet the new requirements, especially in cold weather, after several years of swapping out new larger modules in the design. If the modules that make up the array of an off-grid system produce voltage in excess of the solar charge controller’s Voc rating, the charge controller will likely be damaged and cause the entire system to fail.

- Larger modules can also increase the array current output beyond acceptable levels for an off-grid system’s solar charge controller. While this generally will not permanently damage the controller, it is not good for the controller’s health, and it will cause the charge controller to shut off charging until the current drops down to acceptable levels. In the meantime, the system does not receive power to charge batteries during periods of the day when the sun is offering the most power.

- Larger enclosures may be needed to accommodate larger controllers and other upgraded BOS.

- Shading problems. Arrays that formerly managed to escape nearby shading might now be subjected to partial shading at certain times of the day, once larger modules are swapped-in.

- Supply chain and sourcing issues could pop up if new BOS components are needed. Supply chain and sourcing issues can relate to the new modules themselves and also to new BOS components that are necessary to support the new modules. Prices for new components can be higher, and more importantly, the lead times to receive the required BOS components can be much greater.

- BOM changes as well as design drawing/documentation changes.

- Designers might want to continue to deploy older, smaller modules in some of their systems, but those modules might no longer be available because the industry has moved on from them. Hence, designers might be forced to use larger modules and identify and manage any negative impacts.

- Manufacturer and design company reputations could be compromised. It is important for manufacturers, distributors, and designers to educate their customers to help them know about the consequences and mistakes to avoid when considering module upgrades. Designers’ reputations can either be damaged or improved, depending on how well they communicate and help customers plan for the effects of new modules.

Because of the strong demand from the utility scale grid-tied industry, the trend for larger modules will continue. Since the off-grid market is so much smaller than the grid-tied solar market, it is easy for module manufacturers to overlook concerns related to off-grid system designers. Fortunately, in the long run, as the price of these new larger modules continues to fall, the larger module trend will also benefit off-grid designers, as long as designers identify, understand, and adjust accordingly to mitigate the potential negative consequences.

In the short run however, off-grid designers should be aware of the potential pitfalls of larger modules and make sure to design their systems around them. Changes in module electrical characteristics from year to year, which used to be small and predictable, will now need to be scrutinized more carefully.

For firms lacking dedicated solar design resources, the first step is to consider the benefits of additional education/training and online resources, such as off-grid string calculators, as well as seeking help from experienced third parties to navigate through these changes.

For more detailed information about this topic, you can view a recorded webinar presented by SunWize Power & Battery and Morningstar Corporation right here.

Mark McHenry is the marketing manager for Morningstar Corp., a leader in solar charge controllers and inverters.

— Solar Builder magazine

[source: https://solarbuildermag.com/news/how-large-format-solar-modules-disrupt-off-grid-design/]

Leave a Reply

You must be logged in to post a comment.