Wire management within a solar array is a consistent pain point for solar installation crews. Whether it is zip ties or wire clips, the process can be time-consuming, involve awkward angles, and still result in unreliable or aesthetically unpleasing results. True innovation in this space would simplify everything — can’t this all be integrated on the solar PV panel itself?

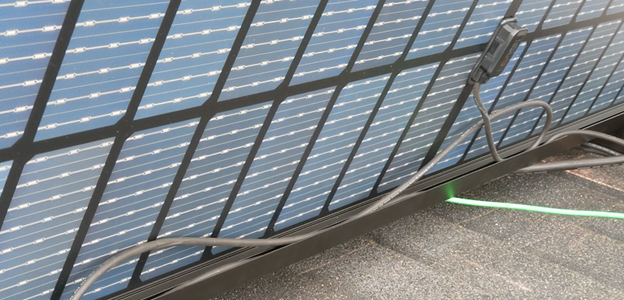

That’s the pitch from SoftPawPV, which launched in Q1 this year. SoftPaw is a wire management channel built as an integral component to a solar panel’s frame, thus eliminating all other wire management devices within the array.

SoftPawPV licenses the SoftPaw technology to module manufacturers and provides engineering assistance to ensure quick and easy integration. Custom SoftPaw designs are also available to accommodate specific applications or combination of wire sizes.

SoftPaw entered the market onboard VSUN 410, 450, and 500W panels supplied through Van Meter, a distributor in the Midwest.

How it works | The SoftPaw channel secures, protects, and hides wires within the array. As part of the frame’s aluminum extrusion, it eliminates compatibility and long-term degradation issues typically associated with wire management devices, and it is located everywhere it might be needed instead of at discrete locations. Since it is part of the solar panel, it is designed to last the life of the panel.

Early installer feedback?

Tucking the module leads into the SoftPaw channel causes them to disappear behind the frame. Since the wires are considered inaccessible while inside SoftPaw, they can pass inspection without triggering the guarding requirements of NEC 690.31. That can save approximately 400’of wire loom, 300 zip-ties, 250 wire clips, and several hours of labor for every backyard ground mount system.

Traditional wire management devices will often fail inspections because, if not set just right, they can come loose between the installation and the inspection. Take a SolarEdge-based array, for example. Installers will often zip-tie all the optimizer wires and home run cables to the rails, which is fairly time consuming and requires preplanning. With SoftPaw, there is no preplan. It manages all the wires while the modules are going down, taking out the slack as they go.

“SoftPaw should be on every module,” says Conner Welch at Rabe Hardware (5 MW/yr). “Why has it taken so long [for module integrated wire management] to happen?”

He also notes that zip-ties and cable clips are difficult to manipulate when wearing gloves. Therefore, while there has been no opportunity for winter installations, the Rabe Hardware team predicts that SoftPaw will provide even greater benefits in winter than it does during the summer.

SoftPaw can also fit two wires at the same location, according to Dean from Eagle Point Solar (20 MW/yr). He uses this feature to prevent sag by looping the wire back onto itself to take out the slack when installing 2-wire microinverter trunk cables as well as DCPM cables.

Dean and his crew found that SoftPaw allowed them to manage all the module leads, completely removing wire clips from their job site.

Since the introduction of SoftPaw, Eagle Point hasn’t had a single wire management related callback or failed inspection. In addition, Dean points out that SoftPaw mitigates critter damage at the jobsite, since critters can’t reach into the recessed SoftPaw channel to chew the wire.

— Solar Builder magazine

Leave a Reply

You must be logged in to post a comment.