This section originally appeared in the Summer 2020 issue of Solar Builder. Subscribe today (print or digital) for free right here.

Church

Load profile: This church in Bakersfield, Calif., is actually multiple facilities. It has two sanctuaries, a gymnasium, offices and classrooms. While certain small areas are occupied intermittently during the week, the primary activities are one Sunday service and an evening service each week. During these services, load is far higher than the rest of the week. Plus, the evening service starts just before sunset — so solar offsets almost none of the peak demand for the week. The facility had an electricity bill of around $40,000 per year — half on an energy charge, half on demand. The 100-kW solar system was sufficient to address the customer’s entire annual energy usage but did essentially nothing to address demand.

Goal: Boost the value (and reduce the payback time) of a solar array with Extensible Energy’s DemandEx load flexibility software by reducing demand charges and shifting energy out of expensive time of use (TOU) periods.

Solution: Software

• 100-kW PV array

• 16 controllable HVAC package units

• Wireless thermostats

• DemandEx Gateway from Extensible Energy

A solar developer approached Extensible Energy about increasing the value of their recent installation through demand-charge management software. The end customer was a mid-sized church in the California Central Valley — a hot, sunny environment. Extensible Energy proposed to control the HVAC systems of the facility through replacement of legacy thermostats with modern wireless communicating thermostats, which would then be controlled by DemandEx software in the cloud. Projections showed that demand could be reduced significantly in at least six months of the year, due to high cooling requirements during church services. Winter months would see little or no savings. Installation was completed in a single day. Aggregate savings from the combination of solar plus DemandEx were projected to be 60 percent of the electric bill, and that target was hit for the entire year.

Payback: Two-year payback on the DemandEx add-on, including all hardware, software and installation labor.

Lifetime savings: Demand savings of 30 percent are achieved without a physical battery. DemandEx savings alone are expected to exceed $120,000 over the life of the project.

Public Safety Center

Load profile: The Public Safety Center for the City of Beaverton, Ore., houses the police and emergency management departments and provides essential community services. The Beaverton Public Safety Center’s peak load is approximately 200 kW.

Goal: Provide uninterrupted critical community services by creating a self-sufficient microgrid with both grid-connected and islanded capabilities. The microgrid needs to supply power using the solar PV and battery assets but can also receive support from underground diesel in the event of a sustained outage when emergencies arise.

Solution: Microgrid

• 250-kW/1,000-kWh battery storage

• 300-kW solar

• 1-MW diesel standby generator

• Microgrid controller from PXiSE

Under the partnership with Portland General Electric (PGE) and the local government, Beaverton Public Safety Center is an example of a new utility business model that supports community resilience, efficient integrated grid operations and enhanced partnerships between the utility and critical service sites. The utility owns the BESS, and the local government owns the solar and diesel to ensure a clear division of assets that allows the utility to prioritize BESS usage for grid services under normal operations. The BESS can discharge to the grid to support frequency, and it can support voltage at the feeder level by charging or discharging in response to system-level needs.

Justifying microgrid projects can be difficult for customers to do on their own based solely on the benefits to a single site. By combining the values of both the site’s local benefits and the utility’s system benefits, a microgrid project can become more financially viable with the twofold value it provides.

This project is designed for endurance and continued operation in the event of an earthquake with the ability to support 21 days of operation. The benefits of having redundant systems, a backup generator and battery storage is an example for other communities that are working toward energy reliability and resiliency as they face the threat of emergencies and natural disasters. The project team supporting PGE, including PXiSE Energy Solutions, delivered a flexibly sourced, cost-efficient, fast-responding, resilient energy system that also supports the city’s climate action goals.

Lifetime savings: In addition to emergency power, the solar panels will cover 40 percent of the building’s usage year-round with excess energy stored in the battery. During emergencies, the center can give power from the solar panels and battery back to the grid. The city will apply its cost savings to the center’s operations budget, making more funds available for other services.

School

Load profile: At Howard Elementary School in Oregon, the seasonal load profile peaks with on-site power consumption during the school day when school is in session. On-site consumption is lower in the summer months, allowing for time-shifting of solar and energy arbitrage opportunities for the Eugene Water & Electric Board (EWEB).

Goal: The elementary school is a Community Point of Distribution (CPOD), a location designated to provide power and water for the public during long-term outages due to natural disasters or other emergencies. Any system in place should enable energy arbitrage, voltage support and peak-shifting for the EWEB to help reduce electricity costs and provide everyday savings for the community.

Solution: Microgrid

• 500-kW solar array

• Two NEC 280-kW/510-kWh lithium-ion energy storage systems

• Integrated battery storage controls

Eugene, Ore.’s water and electric board recognized the risk of long-term power outages from natural disasters that could disrupt its water treatment plant or water distribution system. In light of possible natural disasters and other emergencies, the Eugene Water & Electric Board (EWEB) created a long-term resiliency plan to establish community points of water distribution and power around the city.

The system consists of 500 kW of existing solar which charges two NEC 280-kW/510-kWh lithium-ion energy storage systems sized to power the school and a new well system to ensure fresh drinking water during an emergency. The battery storage system is partially funded through a $295,000 grant from the U.S. Department of Energy’s Office of Electricity and the Oregon Department of Energy. These microgrids will also reduce electricity costs for customers through energy arbitrage, voltage support and peak shifting. WorleyParsons managed the engineering, procurement and construction contract. Eugene Water & Electric Board owns the system and serves 90,000 customers with a peak load of about 500 MW.

Payback period: Five to seven years.

Industrial Warehouse

Load profile: When setting out to build its new corporate headquarters, Santa Cruz-based solar installer Sandbar Solar & Electric had a choice: Plan and pay for the costly, multi-year process of connecting to utility power, or equip the building to run independently from the grid. Interconnection to the local utility was estimated to cost around $75,000 and take 18 months to complete. Once connected, Sandbar Solar & Electric was looking at an average monthly electricity bill of about $1,000.

Goal: Operate the Sandbar Solar & Electric headquarters independently from the utility grid and champion innovative renewable energy technologies.

Solution: Microgrid

• Battery system: Two Blue Ion LXHV cabinets, 64-kWh capacity total, three Avalon 30-kWh FB3

• Power conversion: Two 30-kW Ideal Power 30C3 inverters, one SEL-547 protective relay

• Solar: one 38-kW array, one 21-kW array

• Generator: 50-kW Blue Star natural gas generator with Basler controller

• Controller: Ageto Energy ARC

By adding a Blue Planet Energy Blue Ion LXHV system, Sandbar Solar & Electric was able to increase their load capacity by 64 kWh, as well as benefit from increased efficiency and usefulness from their existing solar resources, while reducing reliance on the gas generator. With a highly-efficient charge and discharge rate, Blue Planet Energy’s battery remains charged without expelling energy, allowing it to store 100 percent of the incoming solar energy and greatly reduce generator usage — and its associated environmental impact and noise. And, as the building’s energy needs continue to expand, the Blue Ion LXHV is fully scalable to 2+ MWh, allowing Sandbar Solar & Electric to easily install additional capacity to the existing system.

Combining all the elements listed above (minus the generator), Sandbar Solar & Electric’s system was designed to produce enough energy to satisfy the building’s energy needs for 96.5 percent of the year. The natural gas generator runs the other 3.5 percent of the time (about 300 hours total). The Sandbar HQ has commercial-grade, 480V, 3-phase power and has remained fully operational through all grid power outages that have affected its local area since the building’s completion in December 2019.

Lifetime savings: Over a 20-year period — not including the $75,000 interconnection study or the carrying costs for every month Sandbar Solar & Electric would have waited for grid connection — utility power would end up costing about the same as a microgrid over the lifetime of the system.

Electric Bus Station

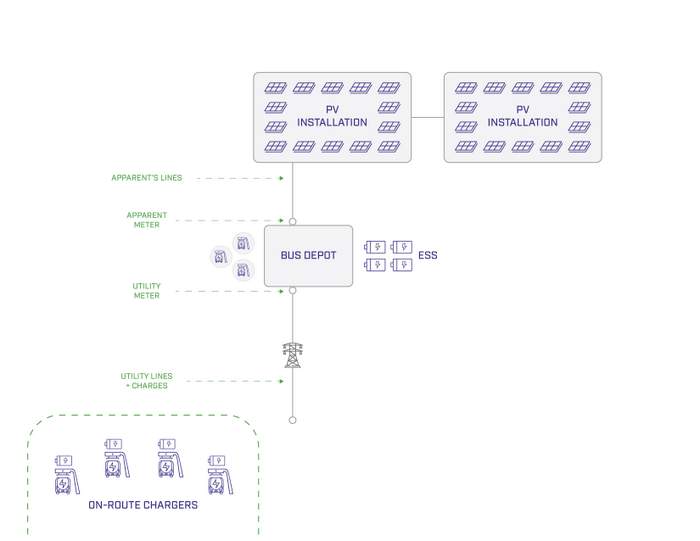

Load profile: A transit authority based in southern California needed a long-term, environmentally friendly and economically feasible solution to charge its electric bus fleet. The transit authority’s local utility had imposed a new rate structure that froze demand charges for five years. But time-of-use (TOU) rates were extended with lowest peak periods in the middle of the day, making it difficult for EV fleets to charge economically by year six, specifically avoiding demand charges. The fleet consists of 80 electric buses, expected to grow to 100 in the coming years. The buses primarily charge at the depot overnight, and some of the bus routes included on-route charging.

Goal: The immediate opportunity was for the electric fleet charging system to support a zero-emission fleet of 80 buses at the lowest sustainable cost. The additional goal was to use the zero-emission fleet and charging stations to provide capacity, voltage support and frequency management to add resilience to the local energy market, to result in additional revenue streams.

Solution: Microgrid

• 16.5 MW of solar

• 20 MW of storage

• SG424U CA 120 Vac smart grid inverters

• Apparent’s Intelligent Grid Operating System (igOS) energy management platform

Apparent’s energy management platform provides a complete solution for managing the complexities of distributed generation. It generates more energy out of the same capacity of distributed energy assets regardless of the source by producing reactive power (kVAR), without sacrificing real power (kW). The kVAR function means that Apparent can produce the exact waveform of energy that is needed, lowering costs and increasing efficiency of solar+storage assets. Apparent’s platform also offers impedance matching, non-export, frequency adjustment and harmonic clipping, each of which reduces energy costs and contributes to grid stabilization.

As a result, Apparent dynamically monitors the eBus’ energy needs and supplies it from the optimal source (solar or storage) for cost savings and system-wide efficiency. It can incorporate changing assumptions and requirements that may arise, such as fleet expansion. In addition to energy cost savings, Apparent’s igOS will improve the power quality at the depot, which will reduce both damage and maintenance costs to equipment, which extends the useful life of the transit authority’s critical equipment.

Lifetime savings: Over the 20-year project life, the transit authority will see savings due to decreased overall energy costs, improved equipment performance and the ability to manage energy costs as the fleet grows. Energy services that cost $6 million less than the local utility and $3 million less than the local CCA’s charges over 10 years.

Chemical & Materials Manufacturer

Load profile: This chemical and materials manufacturing facility experiences an average of 10 outages per year, costing over $1 million annually, caused by utility power shutoffs. Manually curtailing energy to achieve savings required staff effort and was disruptive to productivity. With energy-intensive equipment including injection molders, conveyor systems, semiconductors and chillers, energy bills added up to become a topline expense.

Goal: Use AI-driven software to learn energy usage patterns and to control a battery system paired with a solar PV system to avoid costly demand spikes that occur during the day — without interrupting operations or requiring a capital outlay.

Solution: Solar + Storage

• 1,443-kW/2,886-kWh storage system

• Stem’s Athena AI-driven software

• Entire facility load backup

• Backup duration: 15 minutes

• Transfer time: <200 milliseconds

Facilities with heavy industrial equipment or large air conditioning loads with inductive motors that cycle on and off during the manufacturing process often rack up steep demand charges that can make up more than 50 percent of the utility bill. Some manufacturers spend significant time tracking time-of-use (TOU) rates and energy consumption to lower energy costs. These are usually manual, time-consuming and disruptive processes. Intelligent energy storage automates these processes to optimize energy costs without requiring any staff time to monitor energy rates, manually turn off equipment at certain times or to align production schedules with the utility’s rate schedule. Smartly using energy storage can cut the peaks off demand spikes by injecting stored energy during periods of high energy consumption, eliminating demand spikes and their related costs.

Using Stem’s intelligent energy storage requires no capital investment and began reducing energy costs immediately. By intelligently monitoring and responding to energy use, Stem’s AI for energy storage charges an onsite battery system during low cost electricity periods and discharges stored power during high-cost electricity periods.

Payback period: Zero upfront cost, shared savings payment.

Lifetime savings: Annual avoided outage costs: $1 million; annual utility bill savings: $700,000.

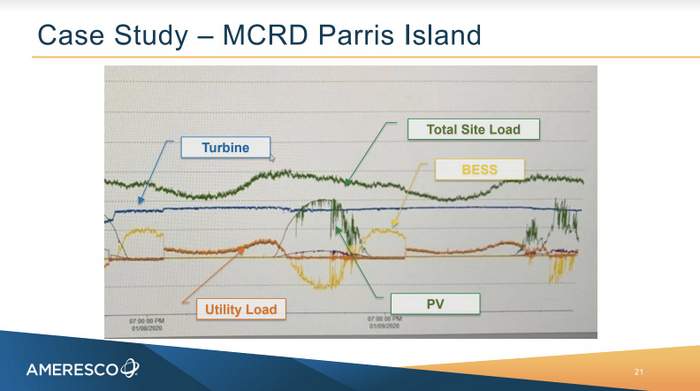

Military Base

Load profile: In 2019, Ameresco completed a comprehensive energy infrastructure project on behalf of the United States Marine Corps at Parris Island in South Carolina. The Marine Corps Recruit Depot (MCRD) Parris Island typically spent roughly $11.7 million annually for utilities (electricity, fuel, and water). Peak summer daytime demand periods bring high-priced time of use energy costs.

Goal: Replace the aging boiler plant but also improve resiliency and assure continuity of mission-critical operations at the base. Reduce baseline utility consumption through energy efficiency and conservation measures so that the remaining, efficient loads could be served more cost-effectively by a right-sized on-site renewable and resilient energy system.

System solution: Microgrid

- 20,000 solar modules (ground-mounts, carports)

- A two-hour lithium ion battery energy storage system (BESS)

- Intelligent microgrid control system

What makes the MCRD Parris Island project unique is the level of automation built into the base’s new utility management system. The intelligent microgrid control system is able to gauge when and where power is needed and determine which resource to draw that energy from. The system responds differently depending on the time of day, the asset generation cost, and the ability to individually support critical loads in a contingency. Should the main utility go down, the microgrid controller adapts its resource dispatch between available assets including the CHP plant, the battery storage system, and PV plants. If the load is too great to serve with those on-site resources, the microgrid will load shed, starting with the lowest priority in order to make sure the critical parts of the infrastructure stay up and running. The system both predicts the best course of action in a contingency, as well as responds to anomalies while they’re happening for greatest authority over operation. The islanding of the system provides long term resiliency and can plausibly operate indefinitely.

As a result of the coordinated operation of all these new on-site resources, actual electric purchases from the utility (orange line labeled “Utility Load” in graph above) are now quite low. This not only results in significant electric cost savings but illustrates just how energy resilient and self-sufficient the Depot now is with its microgrid-controlled on-site generation assets.

Payback period: The U.S. Marine Corps utilized an energy savings performance contract (ESPC) for this project, which allows the Government to avoid any upfront capital cost and utilize the project annual saving to pay toward the amortization payment. a 22-year contract performance period.

Lifetime savings: The estimated cost savings over the life of the ESPC contract is $186 million.

— Solar Builder magazine

Leave a Reply

You must be logged in to post a comment.