PV module technology continuous pursuits in the evolution of high efficiency and high power are the key factors in reducing the LCOE. LONGi Solar says it has developed “Seamless Soldering” technology, which completely eliminates the gap between cells to increase the efficiency of PV modules. According to TÜV SÜD test, Seamless Soldering, when combined with an innovative module design, has the potential to push LONGi Solar’s high efficiency PERC module power record to 500 Wp.

The technology is planned for mass production in the second half of this year.

How it works

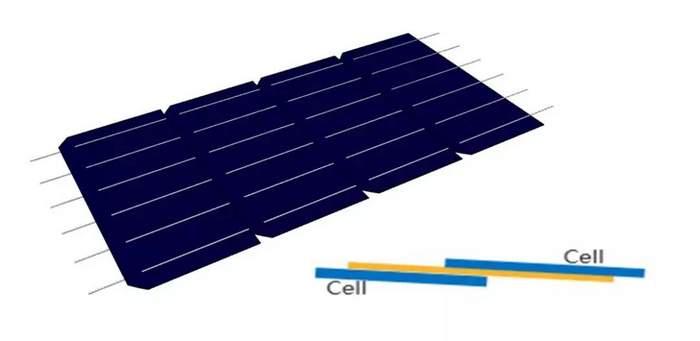

Seamless Soldering technology uses a solder ribbon to achieve “tiled” interconnection of the cell, completely eliminating the typical 2-mm-wide cell gap, thus increasing efficiency while reducing the BOM cost of the module. This technology is also perfectly compatible with its existing module encapsulation processes and equipment, which means it has a high probability for mass production stability, and capacity is easily scalable. In addition, Seamless Soldering can integrate with M6 monocrystalline silicon wafer, thin silicon wafer, soldering wire and reflective ribbon.

LONGi has carried out intellectual property research on Seamless Soldering technology and has applied for a number of related patents.

— Solar Builder magazine

Leave a Reply

You must be logged in to post a comment.