The most important part of a PV mounting structure is the module itself. Along with generating energy, PV modules play a key role in maintaining the overall structural integrity of the entire system. However, they are susceptible to a wide range of mechanical durability challenges that may lead to degraded power plant performance if not properly addressed.

The recent wave of new module technologies and designs — especially larger format modules and thinner frames — are driving greater structural integrity challenges. These trends make the evaluation and testing of module durability and performance more important than ever. This article focuses on several key durability challenges: cell and module damage from cracking and microcracking and issues with larger form factors.

Cell cracking: The hidden durability challenge

With cell thicknesses less than 0.2 mm and module glass thicknesses of 3.2 mm, modules can be susceptible to cell cracking and microcracking. These failure mechanisms can result from manufacturing defects, transportation and shipping damage and improper installation, but racking and mounting systems can also pose risks:

- Extreme weather events such as high winds, severe hailstorms and heavy snow can cause damage when racking and mounting systems are overloaded.

- Ground undulations due to frost heave can put significant strain on the modules.

- Even without extreme weather events, some poorly designed and built racking is failing in the field, causing additional mechanical stress on modules.

One significant issue to keep in mind is that cell cracks typically do not cause power loss right away. They take time to develop into inactive areas and hot spots that drive underperformance and raise safety concerns. This occurs once the metallization across the cell breaks, leading to an open crack.

The potential for power loss also varies by the type of crack, and the resultant financial losses depend on modeled assumptions for the plant. Allowances for lower-than-expected energy yields are usually built into financial models, but they vary by project. For some solar power plants, just a 3 percent loss in production eliminates profits.

A cell crack’s potential for causing power loss is determined by crack orientation and location. Cracks that have the potential to isolate regions of the cell from busbars have a greater risk for long-term energy loss than those that do not. The potential energy impact ranges vary. According to one study, the inactive cell area may cover up to 8 percent of total cell area without leading to any relevant power loss. For approximately 12 to 50 percent of inactive area of a single cell in the PV module, the power loss increases nearly linearly from zero percent to the power of one double string when the bypass diode becomes active. In other words, the power loss of a single crack can range from zero to 33 percent of the entire module’s power output.

Certification testing is not enough

the before and after microcracking (or without and with microcracking, or pre- and post-stress test). They are electroluminescence (EL) images from the PVEL lab

While module certification testing has its place, the existing standards set a minimum bar for participating in the industry, and they do not focus on the eventual fielded durability of the module. They are not meant to determine if a module will perform reliably over the course of its modeled lifetime in a variety of climates and site conditions, let alone guarantee the ultimate performance and bankability of the module.

The main qualification test for PV modules set by IEC 61215 includes static mechanical load testing at a pressure of 2,400 Pa (downforce and upforce), plus an option to extend this to 5,400 Pa downforce for heavy snow areas at the module manufacturers’ discretion. The IEC qualification test also includes hail testing with a minimum requirement of hail balls that are 1-in. (25-mm) in diameter shot at the module at approximately 50 mph. Both of these tests are completed after damp heat chamber testing, with no further stress tests following them.

To pass the requirement, the module must exhibit no visible physical damage and suffer no power loss greater than 5 percent. The IEC standard has no requirement to use electroluminescence (EL) imaging to see if cracking that could later lead to power losses has occurred. This means that many modules that pass the tests may have latent cell cracking issues that do not manifest and initially impact performance. Although the most diligent manufacturers’ own reliability testing surpasses the minimum threshold and subjects their products to a rigorous testing regimen, not every module producer has the same commitment to quality.

Comprehensive testing is crucial

Because of the insufficiency of the IEC standard, developers and asset owners need additional independent data and information to understand how well the modules they are procuring will perform over the lifetime of the plant. They require a constantly iterating, rigorous testing program that goes well beyond the minimal baselines of regular certifications testing and properly qualifies and understands the range of new products coming to market as well as the novel and evolving failure mechanisms that could affect those products.

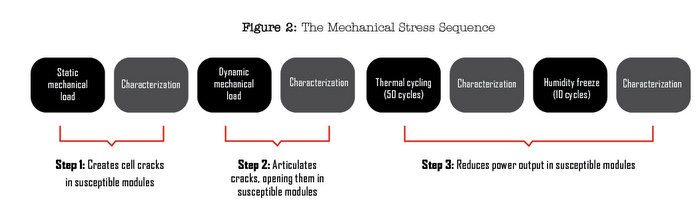

One of these comprehensive testing programs is the PVEL PV Module Product Qualification Program (PQP). The 2019 PQP update added a number of new test sequences, updated some of the characterization steps and made other improvements to provide the industry with solid, actionable data. For the purposes of this article, one new test sequence is of particular interest: the Mechanical Stress Sequence (MSS) for cell cracking and mechanical durability.

The MSS consists of a series of stress tests, each followed by a round of thorough characterization measurements, including flash testing, EL imaging and detailed visual inspection (see Figure 2). The first test is static mechanical loading, which creates cracks in susceptible modules by simulating the field representative loads that cause cell and interconnect cracking. The second test, dynamic mechanical loading, mechanically articulates these cracks, causing them to open in susceptible modules (see Figure 1). The third and fourth tests, thermal and humidity freeze cycling, are designed to further force these cracks open to reduce power output, just as environmental stress can cause cell cracks to reduce performance in the field.

The module types at PVEL in the midst of MSS testing run the gamut of technologies and sizes: monofacial and bifacial; n-type and p-type; 5-, 6-, 9- and 12-busbar; interdigitated back contact (IBC); metal wrap-through (MWT); heterojunction technology (HJT); thin film; full cell, half-cut and shingled; 156.75-, 158.75-, 161- and 166-mm cells; glass/backsheet and glass/glass and more. Never before have so many different module designs been on the market.

This plethora of PV module technologies means there is a range of cracking and microcracking risks. For example, thinner wafers can be prone to easier crack propagation; laser-cut, half-cut and shingled cells may see more edge microcracking; and larger modules might suffer from more deflection and tensile stress from poor handling or from high winds or large snow loads if not properly mounted. Test results will vary, and the industry has already begun to take a number of mitigation measures to reduce cell cracking and lower the possibility of subsequent power loss.

The crack risk can also be lessened with certain configurations or strong testing protocols. Glass/glass modules exhibit little or no tensile stress, while the presence of more interconnect wires means there are smaller disconnected areas. Conductive adhesives found on some shingled-cell modules have shown less microcracking, and parallel wiring (as seen on many half-cut modules) helps reduce the likelihood of the cells entering reverse bias. Better packaging and handling practices leads to less damage during transportation and handling, and thorough EL testing ensures better quality control coming out of the factory as well as in the field.

Impact of bigger modules

The recent power class race of companies introducing very large 400- to 500-W and beyond modules has implications for the designs of racking and tracking systems and the mechanical durability of the PV modules themselves. Although there is not yet enough data to fully evaluate these implications, here is some food for thought on known unknowns regarding these supersized modules:

Single-axis trackers may have difficulty mounting larger modules without extending past the current mounting points and changing the maximum pressure at those mounting locations, which could challenge the durability of the modules. Importantly, there will also be the greater potential for wind damage issues because of the larger surface area of the module. To avoid torsional galloping — caused when a PV module spins out of control around the axis of the tracker — and other dynamic load phenomena, tracker designs may require revamping to meet higher wind engineering standards.

The tight cell layout of some larger modules, often involving a larger wafer size and cut cell architecture, means there is less inactive space between the cells. What will this lack of buffering space between cells mean in terms of the thermal expansion and contraction of the cells, glass and other module materials? The introduction of copper alloys into the cell interconnects, and other bill of materials changes to facilitate these new cell layouts, have not been fully validated.

Dynamic PV module design is exciting for our industry, but as discussed here, it can also be challenging. Without proper qualification and testing, buyers may face undue procurement risk when investing in new technologies. PVEL is evaluating bills of materials and testing modules of different designs from a variety of manufacturers and will have more data later this year.

Tristan Erion-Lorico is Head of PV Module Business at PV Evolution Labs.

— Solar Builder magazine

and Choice

and Choice

Leave a Reply

You must be logged in to post a comment.