This piece was contributed by K2 Systems.

In the early 2000s, the norm for waterproofing roof attachments was a simple L-Foot put directly onto the roof surface with sealant added to keep water out. K2 Systems’ Senior Director of Training, Johan Alfsen, was pivotal in changing this bad practice, which is often referred to as the “goop and a prayer” era. As a solution, manufacturers started creating the all-in-one flashing and mount – a metal flashing solution, similar to what roofers use for waterproofing, with a built-in solar mount.

This popular system is designed to slip between composition shingles and is waterproof once it is lag screwed into the roof structure. It became the standard for composition shingle roof attachments and is still used today.

A metal flashing typically consists of a 9”x12” flashing square combined with a mount or L-Foot that incorporates a waterproofing seal. Solar installers use a pry bar to carefully separate the shingle courses and remove obstructing nails to slide the metal flashing into the correct positioning. On a cool day, this can be an easy task but in very hot climates, such as Las Vegas or Arizona, prying up shingles can be very difficult and can often lead to severe damage to the roof material.

For these reasons, over the last few years, there has been a new wave of non-metal flashing products rising in popularity.

Non-metal flashings eliminate the need to pry up the shingles or remove nails. They are designed with a self-sealing protective layer, like a compatible butyl, that seals as you attach to the roof. There is no need for additional sealant or disrupting the roof’s waterproofing system. These new seals are tested for waterproofing and durability. The simplicity of these types of products saves a lot of time on the roof for solar installers.

So now there seems to be a big debate.

Which is better: traditional metal flashings or non-metal flashings?

Installers in harsh environments need a better solution. They don’t want to degrade the roof nor do they want to risk the liability with the old “goop and a prayer” method. But in some areas, they also don’t want to create more harm than good with metal flashings that are almost impossible to install. The appeal to not have to pry shingles up and remove nails is felt by installers in all areas. Time savings are a must on the roof, but not at the cost of quality.

Recently, there has been a flurry of new non-metal flashing products coming to the market that use sealing pads of various materials and others with sealant pockets. Time will tell if these products last, but more and more manufacturers are doing extensive testing to show the reliability with these non-metal flashing products.

While the solar industry has grown and adapted over the years, it is still challenging to introduce new concepts that move away from industry norms that have been used for decades. Moving from the old sealant-based mounting to metal flashings and back around to non-metal sealing methods has been an interesting ride on the so-called “solar coaster.”

Every job and location has its own unique conditions that require different solutions. Metal flashings will always have their place, but it’s worth exploring the possibilities of new non-metal flashings that are tested and proven rather than just relying on outdated methods.

K2 solutions

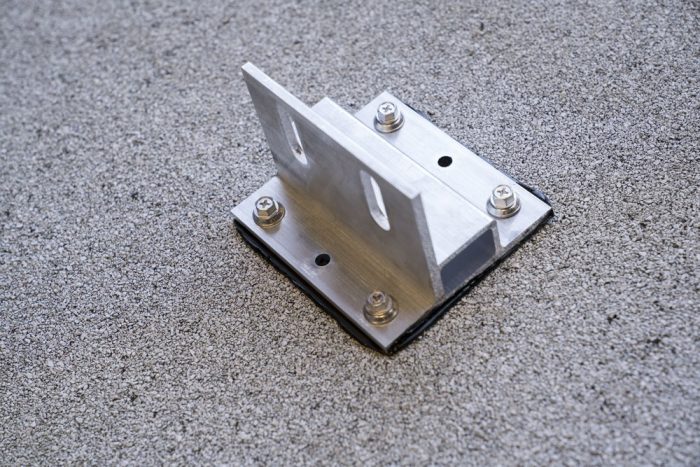

A few years ago, K2 Systems launched the Splice Foot X & XL series of roof attachments. The Splice Foot is a roof attachment with a simple design loaded with problem-solving features. With two rail channel slots built into the mount, the Splice Foot acts as a standard attachment to the rail and can also act as a structural splice attaching two rails when needed.

The Splice Foot also comes with K2’s built-in specialized butyl seal, the K2 EverSeal, to eliminate the need for splitting shingles and removing nails with traditional metal flashings. The K2 EverSeal uses waterproofing technology that has been tested for rain, water submersion, salt spray, extreme temperature variations, age simulation, and much more. It is a specialized butyl rubber that is resilient, reliable, and resistant to the harsh elements found among rooftop solar mounting systems. The structural mounting screws that are included with the mount are 5mm self-tapping screws that require no pre-drilling. They are designed to pull the butyl into the rafter connection, eliminating the need to add sealant to the penetration.

The Splice Foot roof attachments have proven to be very popular in the market, so K2 is working on expanding its roof attachment offerings with K2 EverSeal.

To stay up to date with K2’s product releases, you can sign for their newsletter here.

— Solar Builder magazine

[source: https://solarbuildermag.com/news/non-metal-flashings-vs-traditional-metal-flashings/]

Leave a Reply

You must be logged in to post a comment.