This article appears in the Spring 2020 issue of Solar Builder. Subscribe here for free (digital or print).

With fewer ground-mount solar sites featuring flat, open terrain, we’re fortunate to have a new generation of fixed-tilt and tracker systems that offer greater flexibility and slope tolerances. By adjusting the post heights under the tracker or table, mounting systems can compensate for unlevel ground and make solar possible on sites with hills or uneven terrain.

However, there are limits to the range of post height adjustment. If a post is too tall, structural forces such as wind and snow loads and the weight of the tracker itself become too great. And though taller posts can be made possible with stronger foundations, practically speaking, most projects use a uniform site-wide foundation size. On the other hand, if the posts are too short, you risk bottoming out the table or allowing the tracker edge to interfere with the ground. Exceedingly short posts may also pose problems by failing to provide sufficient clearance to mount gear boxes, electrical equipment and wire harnesses to the posts.

To determine whether a mounting system can be installed on a site with uneven terrain, most developers have relied on slope analysis — or the computation of the average grade underneath each tracker or table. Slope analysis doesn’t take the post height limitations into account, however, and going beyond slope analysis to model every post in a utility-scale layout was too time consuming to be practical. Now, thanks to advances in modern cloud computing and data analytics, pier analysis is possible for the first time, increasing the accuracy of project modeling and site assessment, reducing both material and manpower costs.

Drawbacks to slope analysis

The science of slope analysis uses an aerial site view to look at the height of the ground under the near end of each tracker or fixed-tilt system and the height of the ground at the far end to compute the average grade for the row. The problem is, a tracker row can be 300 ft long or more, and there is a lot that can happen along the row length that is not accounted for in an average grade. For example, what if there is a significant divet mid-row? In that case, the pier in that location will be taller than the maximum allowance, making the system vulnerable to forces that could cause it to fail or blow over. Or conversely, what happens if there is a small hill mid-row? In that case, the post would be too short and the tracker could bottom out in that location.

Slope analysis makes a project vulnerable to “false positives” and “false negatives” during the site suitability assessment process. A consideration of slope averages might lead one to believe that a site is constructible, while on-site realities prove the opposite. Or, slope analysis might reveal an average slope that is slightly more than manufacturer specifications, causing a tracker or ground mount site to be dismissed. In fact, it may be that simple post height adjustments along the row could have compensated for the slope and made the tracker installation possible.

Advantages of pier analysis

The science of pier analysis starts with manufacturer-specified post spacing and triangulates each post location with the three, closest-available topo points as defined by either publicly available topography databases such as Google Elevation Services and USGS data or survey data from a commissioned ground or drone survey of the site. Today’s most advanced solar design software can complete these computations and calculate the unique post height for every pier on a project site in a matter of minutes.

In addition to a far more accurate assessment of site suitability, pier analysis also provides distinct advantages when it comes to project costs and installation efficiency.

Costs

With a project plan based on slope analysis, all piers are manufactured at a uniform height, which is typically taller than the analysis calls for to allow for on-site adjustments of each post during installation.

By contrast, with pier analysis, every post is sized to the requirements of its unique site location. The result is less steel and lower material costs.

Pier analysis also allows for a more accurate evaluation of increased post-height vs. grading costs. Project developers can determine with certainty whether investing in more steel and/or stronger foundations is less expensive than investing in site grading.

Installation efficiency

As mentioned above, project plans based on slope analysis anticipate the need for on-site adjustments in which piers may need to be pounded deeper into the ground or cut down in order to meet the real-world requirements of uneven terrain. This requires an investment in heavy equipment, as well as additional installation time to take corrective action. In a worst case scenario, installation crews may get to a site only to realize that it is impossible to install the posts within the required range to compensate for the actual terrain underneath the mounting system, leaving no choice but to remove the tracker from the system or do costly unanticipated rework such as grading or installing custom foundations.

With pier analysis, every post is sized to spec, eliminating post-height-related slowdowns during project construction.

Finally, because advanced software is able to complete a site-wide pier analysis in just minutes, it can be used as a project development tool to inform tracker or fixed-tilt system selection. With the ability to quickly create layouts for an unlimited number of manufacturers, it is possible to choose a mounting system based on which manufacturer and model requires the fewest number of foundations or the least amount of steel.

Let’s Consider an Example

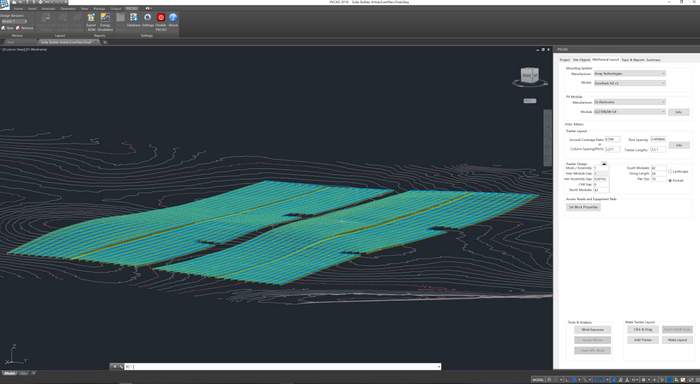

Let’s consider an example, below is a layout of a 7.5 MW single axis tracker project using 350W solar modules. The project has 248 full length trackers with 3 strings of 28 modules per tracker and 11 piers under each tracker, plus 8 partial length trackers with only 2 strings per tracker to make room for the nested equipment pads:

Structural calculations show that the piers require a minimum embedded depth of 4’ in the ground. Tracker manufacturer requirements specify a minimum of 4’ reveal above the surface of the ground and a maximum of a 12’ foot reveal above ground. The latest quote from the steel supplier tells us that the piers will cost $9/linear foot. the site requires 2776 piers in total. The site is on hilly terrain.

A quick software pier analysis will give us the following information:

| Embed | Reveal | Total | #Piers | Cost/Pier | Extended

Cost |

| 4’ | 4’ | 8’ | 1012 | $72 | $72,864 |

| 4’ | 5’ | 9’ | 453 | $81 | $36,693 |

| 4’ | 6’ | 10’ | 343 | $90 | $30,870 |

| 4’ | 7’ | 11’ | 251 | $99 | $24,849 |

| 4’ | 8’ | 12’ | 205 | $108 | $22,140 |

| 4’ | 9’ | 13’ | 174 | $117 | $20,358 |

| 4’ | 10’ | 14’ | 158 | $126 | $19,908 |

| 4’ | 11’ | 15’ | 118 | $135 | $15,930 |

| 4’ | 12’ | 16’ | 62 | $144 | $8,928 |

| Total | $252,540 |

Based on this result we can evaluate 3 possible strategies: the first is to grade the site, which would allow 8’ piers to be used everywhere (4’ below ground + 4’ above ground). The direct cost of steel piers would be 2776 x $9 x 8’ = $199,872 ($0.027/Watt). This is the lowest cost option for piers, however, site grading is very expensive and could easily end up costing more than any savings, and it’s also very destructive to the local environment and will add weeks to the project schedule. The second option is to buy 16’ piers everywhere, and then either cut the piers to the proper height in the field or level them under each tracker by pounding them further into the ground where necessary. This would cost 2776 x $9 x 16 = $399,744 ($0.054/Watt) and adds extra labor costs to the project and will “waste” a significant amount of steel. The third option is to order each pier at the proper length based on the pier analysis, which would cost $252,540 ($0.034/Watt). This represents $147,204($0.02/Watt) in savings compared to the second option, and doesn’t require site grading.

Conclusion

Performing a detailed pier analysis on a utility scale solar project is preferable to a simple slope analysis, and modern software tools make it easy to perform. A pier analysis reveals valuable insights that can mean the difference between several cents per watt in project costs and avoids false positives and false negatives when evaluating tracker constructability.

Daniel Sherwood, P.E. is president and co-founder of solar design software company, PVComplete.

— Solar Builder magazine

Leave a Reply

You must be logged in to post a comment.