Whether you build, operate or own utility-scale PV, managing costs while ensuring quality is top of mind for all involved. At first glance, cable management might not be as critical as modules or central inverters. Over time, cable management issues — specifically cable tie failures — can affect a site’s performance, leading to substantial cumulative revenue losses.

A failed cable tie can lead to a downed wire and potential inverter ground faults. Adding to regular wear and tear, extreme environments such as deserts, where temperatures can range from -20°F to 120°F, can further stress materials. There are many considerations to getting it right the first time and ensuring proper operations and maintenance (O&M) as you go.

To assess how cable ties perform in extreme conditions, we embarked on an industry-first study to compare four solar ties with varying material profiles in the same application on a single site. This article reports initial results of this multiyear comparative study. We also highlight cable maintenance best practices to help streamline work onsite.

Background

Last fall, Solar Support set out to perform routine cable remediation work for Clearway Energy Group at the Blythe 1 Solar facility, in Blythe, Calif., one of the first large-scale PV systems installed in the United States. Clearway is part-owner of Blythe and one of the largest renewable energy asset managers in the country. To further our joint understanding of zip tie longevity, the partners reached out to manufacturer HellermannTyton to explore wire management performance and best practices in extreme environments.

Together, we designed and implemented a multiyear comparative field study to test different material properties. We divided Clearway’s 20-MW portion of the Blythe facility into four parcels and installed different solar ties on the four color-coded sections. The cable remediation scope of work did not warrant complete replacement of all existing ties but rather only failed cables.

This feature appears in the upcoming Q1 2021 issue of Solar Builder. Subscribe for free (print or digital or both) right here.

Zip ties tested

Two considerations are important when evaluating cable tie options: 1) materials and price points and 2) the application of the system. In total, 5,000 of the four different materials were installed on the Blythe site in the exact same application.

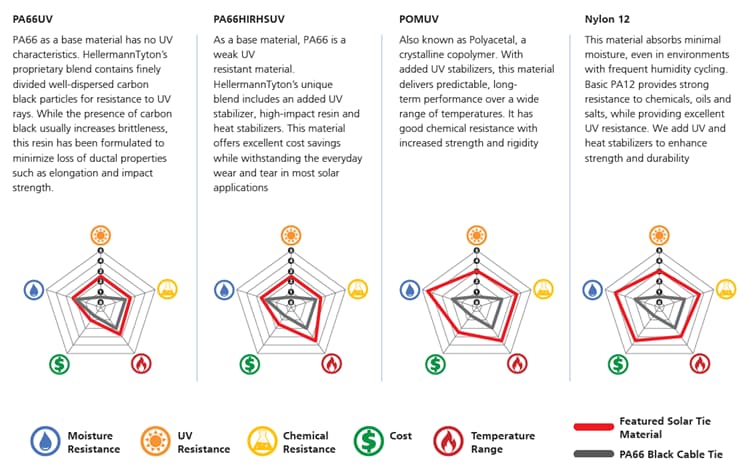

HellermannTyton proposed replacing the failed cable ties with Solar Ties made with polymers designed to sustain conditions such as moisture, heat and other environmental conditions found in the desert. These ties, designed to last 10 to 20 or more years in the field, undergo stringent thermal cycling and other accelerated environmental tests in the lab but had never been tested in a constant environment on the same site. The HellermannTyton Solar Ties used (Graphic 1) all have different chemical and material compositions. The ties were selected because the engineered polymers have temperature ratings of 230°F compared to 185°F for standard UV-rated ties. The higher temperature rating should help protect against constant thermal cycling over the life of the project.

Breaking the tie

This fall, precisely one year after the initial installation, Solar Support revisited Blythe to assess how the untouched original ties were holding up to the elements. Many of the old ties had failed and were replaced with the new solar ties featured.

Made with polymers designed to last decades, none of the new polymer solar ties were expected to fail after just one year in the field. Still, we wanted to know more, and the partners saw an opportunity to conduct lab tests to see how they held up after one year at Blythe. Solar Support collected samples of 10 ties from the blue, yellow, red and green parcels and shipped them back to HellermannTyton’s U.S. headquarters. A sample of the older ties installed five to six years ago was added to the mix.

A split mandrel tensile test was used to determine the maximum load capacity to the breaking point that each tie could withstand compared to the baseline loop tensile strength rating. The first of the results up for discussion are the Nylon 66-based materials, from the red and yellow blocks. These are made of UV and UV/heat stabilized polymer as well as an impact modifier that helps to retain the flexibility even after suffering changes in moisture content. These two materials tested remarkably well, averaging two times or more of their rated tensile strength. After one year of field installation, these parts show no significant issues and should have no problem lasting 15 years, or more, in this application. This was to be expected due to the hygroscopic nature of Nylon 66, — it releases and absorbs moisture based on the surrounding conditions.

The dry climate of Blythe is starting to show in the ties. As cable ties dry, they get stiffer. While these cable ties were not dried out, they are not as elastic as they would be new. This is not a negative, per se, but an effect of heat and UV ageing.

The other two blocks of ties are made of PA12 and POMUV, which are non hygroscopic. These ties tested lower than the red and yellow blocks, but still provided good results. They tested roughly 1.6 times their initial rated tensile strength. The increase in loop tensile strength is a sign of UV degradation in the early stage, but in this case is not showing any detrimental effects.

Tie it all together

This test taught us volumes about why solar ties fail. Here is a summary:

1. Temperature is a factor. Base plastics not designed for harsh environments can erode fast. Think spaghetti in a strainer. When you leave the spaghetti in the strainer it molds to the shape, but adding hot water or some type of fat makes the spaghetti lose that shape. The same goes for plastic. Add elements like heat, and those polymers start to untangle.

2. Standard zip ties (including nylon ties with UV additives) are hygroscopic and subject to drying out over time.

3. In a weather event, basic nylon ties will dry out in the heat and re-absorb the moisture in the environment, picking up zinc chloride and other minerals, which enters the cable and destroys it from within. This is super important to understand because tracker and fixed-tilt systems are often made of galvanized steel, which corrodes over time, leaving a bunch of zinc chloride.

4. UV can play a role, but most of the time the only sunlight that contacts wire management parts is refracted from the ground.

The key is understanding moisture and plastics. This is why our study compared ties made from regular UV-rated nylon with three other ties made from a higher grade of non-hygroscopic, engineered polymer. As time goes on, moisture, heat and UV take their toll on plastics and material selection, and understanding this is an important step in the wire management specification. Different climates will warrant different materials and the cost/benefit of using higher grade polymers will differ in all environments.

Whether you are an EPC building sites from the ground up or an O&M provider keeping them running, you can save valuable resources by selecting materials that are engineered for high heat and UV environments. Using higher grade materials will last longer in the field, require less maintenance and keep labor and replacement costs low, but will cost more upfront.

And don’t forget your long-term plan

When it comes to O&M wire management, due diligence up front is key. Investing the time to survey a new site and putting a plan together can save money down the road by preventing wire damage due to contact with metal edges and junction box wire bends that are inappropriate or unsuitable for the product application.

Product applications to keep in mind:

- On tracker systems, install wire management every 4 ft or less along the torque tube or secured to the module frame. Ensure cable has some slack to allow for thermal cycling.

- Avoid sharp edges. Do not thread products through module mounting holes alone. Movement can lead to premature damage and product failure.

Be sure to create a plan for consistent evaluation after installation. One idea is documenting failed parts. Parts will fail moving forward, but documentation and ongoing monitoring can help prevent or identify these issues before becoming persistent pains. Taking before and after pictures and tracking your inventory can make a difference.

The Authors

Noel Myers, “Solar Cowboy” and Project Manager at Solar Support brings his plant reliability expertise to owners and operators of utility-scale PV. Together with the Solar Support team, Noel offers objective equipment knowledge to help asset owners resolve complex issues that boost uptime, cut costs, and maximize production.

Phil Walker, National Sales Manager at Energy at HellermannTyton North America brings 14 years in the PV industry. Phil has delivered training for EPC design engineers to select “Life of System” wire management for utility PV projects throughout the country.

— Solar Builder magazine

Leave a Reply

You must be logged in to post a comment.