At RE+ this year, I was speaking with a tier 1 solar installation company. I thought they might want to chat about ways to solve the costs associated with overlapping software systems, or inaccurate system designs — but they didn’t. Instead, they told me that they are having to scale back their sales because they can’t keep up with installs. This means a reduction in sales people, elimination of out-bound marketing, and saying no to people who walk through the door.

Turns out the issue for that installer wasn’t a shortage of people installing, it was complexity in the early stages of the design process that was artificially limiting their capacity. Inaccuracies in preliminary design measurement meant that projects often required change orders. The back and forth between the customer, installer, finance partner and sales rep was taking days longer than necessary for every customer.

Unnecessary labor toll of change orders

As solar demand surges and more companies enter the market, solar installers will struggle with soft costs. In fact, although the cost to install solar PV has dropped by more than 70% over the last decade, soft costs—including installation labor, customer acquisition, permitting, inspection, and interconnection—remain high. On average, soft costs represent 65% of the total solar project cost, but perhaps not in the way you think.

A residential system’s hard costs represent approximately 35% of the total system cost. Soft costs account for 65% of the total system cost for residential solar installations and are typically divided into six main categories.

- The largest category is overhead (general and administrative) and profit, representing 21% of the total system cost.

- Sales and marketing costs, frequently referred to as customer acquisition costs, account for 18% of the total system cost.

- Supply chain costs make up 9%,

- Permitting, inspection, and interconnection 8%,

- Installation labor 7% of the total system cost.

- Finally, sales tax accounts for 2% of the total costs.

The most prevalent issue for the industry among soft costs is the continued struggle to find enough labor in the early design phase of a project to meet the growing demand. Basically, change orders, which are often related to design and cost of the system, are costing solar providers too much money.

Aurora Solar ran a quick research poll on change orders, finding that of the 76 individuals who responded to the question about how prevalent change orders are at their companies, 47% reported that change orders impact between 10 and 30% of their projects.

Their research also shared that while the greatest number of respondents (34%) indicated that their change orders cost on average less than $250,

- a similar number (31%) indicated that change orders can cost up to $750.

- 21% of respondents reported that their average change orders cost between $750 and $1250.

- 13% reported change orders costing as much as $1750.

A weighted average generated from these results yielded an average change order cost of $583.

But those costs only take into account the actual cost of the order to the customer, not the cost of manpower hours necessary to make changes, re-estimate and negotiate financing.

Say it takes a residential project administrator approximately one hour to compile application documents regardless of system size. For small business owners, this is manpower that would be best spent on new orders.

The change order cost estimate also doesn’t account for the cost of lost time for a customer. In fact, 8% of solar contractors reported losing sales after a change order.

The solution to reducing these costs is actually through creating more accurate and reliable estimates from first inquiry; if we can trust in the initial designs, we can also create trust with consumers. I don’t say this as a representative of a company delivering solar data, I say this as someone who cares about meeting the demand of solar with the best in class products and services.

Starting a project with accurate site data has a positive impact on every step of the solar sales cycle. High-quality data empowers solar companies to drive down customer acquisition soft costs, which account for 18% of the total cost of a residential system installed in the US in Q1 2020.

The power of data accuracy

All platforms and software companies who provide solar solutions must improve the data they are using to drive first-cost estimates. As an industry, we need to acknowledge the role that inaccurate data is having on our capacity to win over customers. When customers feel scammed by their data, the entire industry struggles.

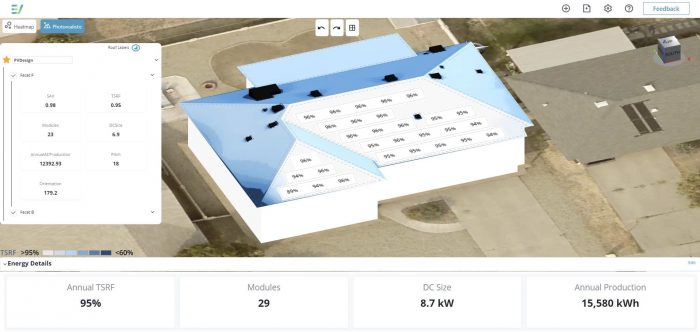

Accurate, installation-ready designs incorporate virtually measured roof azimuth, pitch, and solar access values to guide the optimal placement of modules on the roof, resulting in a portfolio of high-performing systems. In turn, these high-quality designs minimize the possibility of change orders, speed up the permitting process, and shorten the overall project timeline.

Solutions that offer high-accuracy virtual site assessments and installation-ready designs transform company workflows. From customer acquisition and design through installation and project close-out, they create a clear path to drive down costs, increase profits, and free up personnel and financial resources. Ultimately, these solutions enable solar companies to build momentum, scale, and succeed where others might fail.

By improving the accuracy of first proposals and streamlining the pipeline from sale to install through more holistic software tools, more roofing installers will be able to meet surging demands.

Pete Cleveland is VP of Solar Business at EagleView. Pete began his solar career in 2010 where he initially focused on developing and implementing system design standards and processes leveraging his previous experience in land surveying and heavy site construction. Before joining EagleView in 2018, Pete drove innovation and efficiencies with one of America’s largest EPC’s by combining LEAN business practices with technology. Pete now applys technology to solve real world problems in an effort to deploy more solar for the benefit of society and our planet as a whole.

— Solar Builder magazine

Leave a Reply

You must be logged in to post a comment.