The use of solar string inverters impacts AC collection systems across commercial, industrial and utility-scale solar PV projects. If peak solar project operating conditions are ignored when sizing the AC collection system, it can lead to equipment overheating, nuisance tripping, system failure and reduced power generation. Adding complexity to the issue, applicable industry standards for circuit protection are insufficient for these PV systems because the operating conditions are atypical.

It is essential to understand actual project operating conditions for the proper selection and sizing of circuit protection, enclosures and connected cable systems for cost-effective and reliable performance of the project for years to come.

How to design for peak operating conditions

Overcurrent protection devices provide vital functionality enabling cost-effective and reliable performance of PV systems using string inverters. Circuit protection devices, associated enclosures and connected cables are a system. In this system, each component is dependent on the other for effective thermal management. For this reason, designers must account for the peak environmental site conditions to properly size and apply overcurrent protective systems.

Peak site conditions act individually or in concert to increase the operating internal temperatures in enclosures and stress components beyond design ratings. A few of the critical “red flags” that should be considered include:

- Equipment location: The specific site of the installation, such as ground or rooftop, desert or mountain region, will ultimately impact environmental factors.

- Elevated ambients: Ambient operating temperatures above 40ºC will impact the thermal rating of equipment.

- Solar radiance: Direct or reflected exposure adds incremental temperature rise in enclosures and should be considered prior to specification.

- Altitude: Geographical elevation above 6,600 feet reduces thermal cooling in enclosures and ratings should be adjusted accordingly.

Start specification by following codes and standards

Like typical equipment specification, the selection of overcurrent protection devices starts with applicable UL and NEC standards and guidelines. A couple of important considerations for overcurrent protection systems include:

- UL 489 Molded case circuit breakers (MCCBs) are rated at 80 percent continuous current in enclosures, unless they carry a UL listing for 100 percent rating.

- UL 489 MCCB continuous current ratings are calibrated at 40ºC and have cable terminals rated for 75ºC cable ampacity.

- Size MCCB cables at 75ºC ampacitites per NEC Article 310.

- NEC Table 310-16 provides the allowable 75ºC ampacities of insulated conductors based on 30ºC ambient temperatures and provides thermal correction factors for ambient temperatures above 40ºC.

- UL 67 Panelboard and UL 891 Switchboard enclosures are rated at 30ºC average / 40ºC maximum ambient and require cables sized at 75ºC ampacities.

The importance of properly sized circuit protection

Over the last two decades, solar PV systems have evolved to become more efficient, intelligent and effective thanks to the development of highly sensitive modules, inverters and control systems. However, the critical roles of these pieces of equipment necessitate the need for effective electrical protection systems to protect against overcurrent, overvoltage and isolation events.

When designed and specified properly, circuit protection systems can optimize the capabilities of renewable energy generation while keeping equipment investments safe from harm and from downtime. The most critical part of this process is to first understand the unique environmental challenges of the solar installation site before specifying overcurrent protection systems accordingly.

PV module output changes with the operating temperature and the amount of sunlight it is exposed to. The amount of exposure is dependent on many environmental considerations such as irradiance level, angle of incidence and the shading effect from trees, buildings and clouds. PV fuses and circuit breakers are directly influenced by ambient temperature. Thus, the PV system’s overcurrent protective devices should be derated according to the manufacturer’s published curves and UL/NEC requirements.

Ten tips for overcurrent protection specification for AC collection systems

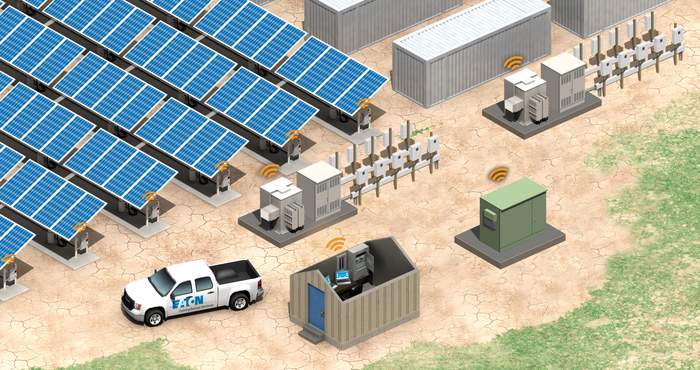

Although the process of evaluating each site’s unique operating environment before specifying overcurrent protection systems may seem challenging, it is relatively easy to avoid common mistakes. From Eaton’s deep experience in solar PV system and circuit protection system design, here are 10 best practices for successful specification:

1. Upsize component ratings as required to offset peak conditions, decrease heat rise and ensure internal enclosure temperatures are maintained within design ratings.

2. Apply molded case circuit breakers properly at 80 or 100 percent continuous current ratings in enclosures.

3. Apply manufacturer’s thermal rating factors for continuous current to upsize circuit breakers in applications where ambient operating conditions are above 40ºC.

4. Consider adding extra design margin when selecting circuit protection ratings and cable loading.

5. Upsize connected cables to the circuit breaker and enclosure terminals using thermal rating factors per NEC 310 and apply those cables at 75ºC ampacities, even if the cables are rated for 90ºC.

6. Add space between densely packed, highly loaded circuit protection devices to improve convection cooling in the enclosure.

7. Follow the manufacturer’s thermal rating factors at altitudes above 6,600 feet.

8. Account for added impact of solar radiance on internal enclosure temperatures.

9. Consider properly sized circuit breakers with thermal-magnetic trip units to provide cost-effective and reliable protection. They become more sensitive to trip as temperatures approach the maximum ambient rating considered.

10. Also note that circuit breakers with electronic trip units are insensitive to changes in ambient temperature from -20ºC to 55ºC but are subject to the above practices to provide reliable performance in peak operating conditions.

Larry Connor is a senior application specialist at Eaton.

— Solar Builder magazine

Leave a Reply

You must be logged in to post a comment.