This piece was submitted by K2 Systems

Tile roofs are a common roofing option in large solar markets such as California, Arizona and Florida. They come in varying shapes, sizes, and materials. Modern tile roofs are built using heavier-duty concrete tiles that interlock, while traditional tiles are made of clay and can be fragile. Underlayment materials are also used on tile roofs, similar to composition shingle roofs.

However, tile roofs have a gap between the tile and decking surface, which makes the underlayment the most critical part of the waterproofing of the roof. Some jurisdictions will require a “primary flashing” at the underlayment level as well as a top tile flashing. This can be challenging for solar installers, particularly when retrofitting, as they may need to use roofing tars, additional underlayment, or adhesives, which creates more labor.

Many jurisdictions have strict primary flashing requirements. The most thorough way is called three coursing with roofing cement, where installers use tar around a metal flashing to flash it in at the underlayment level and then add a layer of mesh and another layer of tar. This process is time-consuming and messy, making installers eager for better solutions.

K2 Systems has addressed the concerns of installers who work on tile roofs and has created a solution to eliminate and save time. K2 Systems has a full range of tile hooks for the different types of tiles, such as flat, S and W tiles.

Recently, K2 Systems has incorporated the same butyl used in their Splice Foot products, called the K2 EverSeal. This flexible flashing butyl rubber that is proven to protect roofs from water intrusion for over 20 years. The K2 EverSeal was first launched with the Splice Foot X and XL roof attachments, but it is now also available on the Universal Standard Hooks and Flat Tile Hook X.

Using the EverSeal is better than metal flashings on asphalt shingle roofs because no sealant is necessary, and there’s no need to pry up nails or shingles, which can risk damaging them. For tile roofs, using EverSeal eliminates the need for labor-intensive three coursing. One K2 customer who used the Flat Tile Hook X with EverSeal claimed to have saved three hours on the job.

Install explained

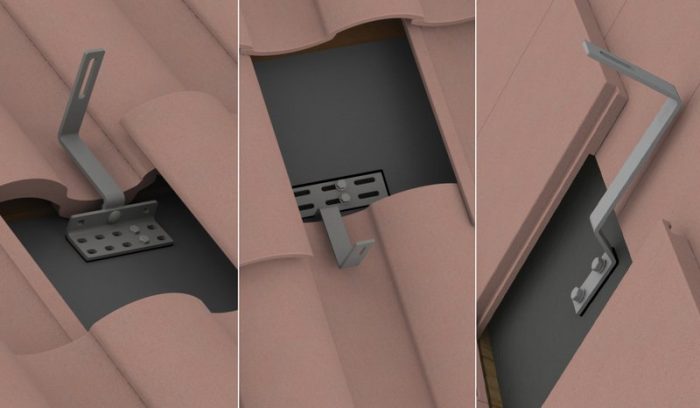

To install the K2 EverSeal on tile roofs, you first need to find the rafter, mark your drill points, and drill your pilot holes. The lag screws are 5/16” in diameter so be sure to drill 7/32” pilot holes. Then, you can remove the paper backing, place the hook down on the marked location, and drill in your lag screws. Torque the lag screws until the rubber bonded washer is compressed flush to the mount.

The pre-installed EverSeal on K2’s tile hooks eliminate the need for messy sealant-based methods to install sub flashings under the tile.

Tile hooks with butyl provide an easier solution for installers who want to seal the penetrations into the tile roof into the underlayment without using big buckets of tar and doing three coursing. Installers can use the butyl that self-seals into the roof. K2 Systems’ tile hooks are available with butyl as a part of the EverSeal series. Installing the K2 EverSeal is clean, quick, and easy.

Give it a try on your next PV project.

— Solar Builder magazine

[source: https://solarbuildermag.com/news/the-benefits-of-non-metal-flashings-for-tile-roofs/]

Leave a Reply

You must be logged in to post a comment.